Factory source Laser Cutting Machine Components - Laser cutting (cutting,bending, welding) – Tuoou

Factory source Laser Cutting Machine Components - Laser cutting (cutting,bending, welding) – Tuoou Detail:

The Laser cutter works by directing a high powered laser beam very precisely at the chosen material to either etc, mark or cut right through. When cutting, the laser beam burns away at the material leaving you with the cutout shape that you have specified in your vector file. The cutting beam is very thin (typically around 0.1mm) and precise resulting in incredibly detailed and accurate cuts.

Traditionally laser cutting has been used by engineers to cut complex parts for machines. It required the use of specialty CAD software to create the vector files that the machine could understand, it required expertise in part design and fabrication to use and it needed high volumes of production to justify the cost.

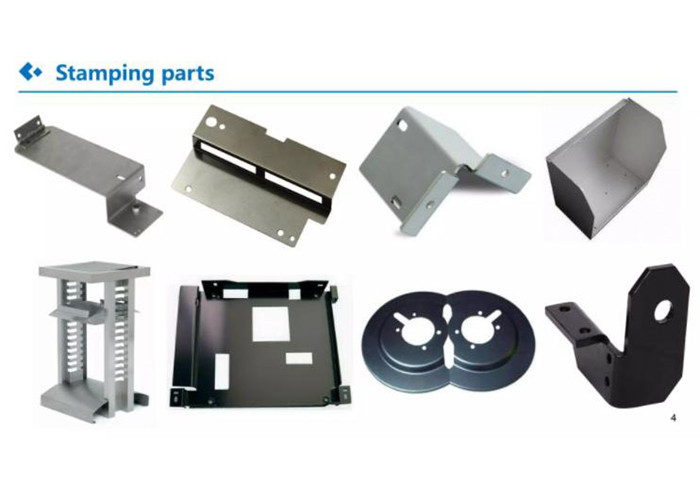

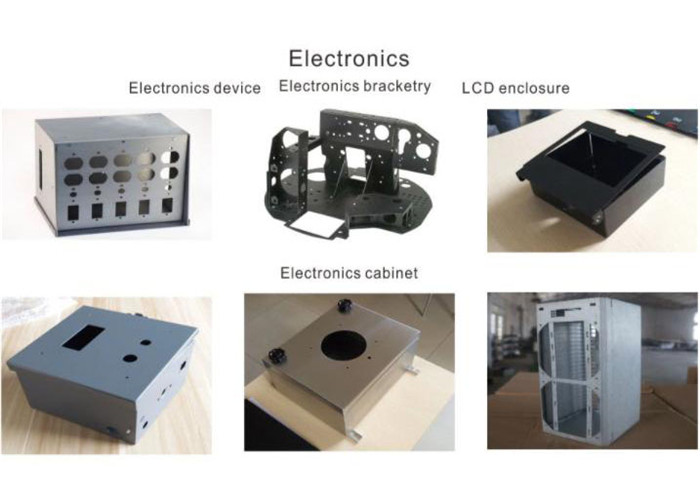

OEM&ODM One-Stop Service in making various kinds of metal parts with a wide range from precision metal parts to large sheet metal stamping parts. According to customer’s order quantity,we offer the most cost-effective way to your project, we can use laser cutting, single-shot or continuous progressive die automated production.

Material

1.Stainless Steel:AISI303, AISI304, AISI316F, 420,440,etc.

2.Aluminum: Al6061, Al6063, Al7075, Al6082,etc.

3.Brass:C36000, C37700, Hpb59-1, H62, C27200(CuZn37),etc.

4.Steel: carbon steel, alloy steel, etc.

5.Copper

6. Plastic : ABS,PP,PVC, POM, Nylon etc.

Process type:Stamping, drilling, grinding, machining, welding, Laser cutting,wire EDM cutting, CNC machining etc.

Surface treatment:Sand blasting, polishing, Anodize, zinc/nickel/chrome/ plating,

Power coating, passivation,Heat treatment, etc.

Applied Softwar:PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Industry Standards:DIN/ ISO 9001:2008 RoHS complicant

Tolerance:0.01-0.05mm can also be customized

Dimension:As customers’ request

Minimum Order Quantity (MOQ):100 pieces

Production Capacity:100000 pieces per week

Trial sample time:Almost 7-15days after confirmation

Delivery time:15-20 days from deposit

Packing detail

1.Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes

2.As customer’s specific requirements

Payment Term:T/T, Escow, Paypal, Western Union, Cash,E-checking,Credit-card,

Major Equipments:CNC turning/milling machine,CNC stamping machine

Drill machine,Grinding machine,Riveting machine,Tapping machine

Trade assurance

Quality controlRoHS tester , callipers , salt spary tester ,

3D coordonate measuring instrument

Other Service

OEM &OEM, Customized Specification, Free Samples

aditional

1)Sample Order and Small Order are acceptable;

2)The methods of delivery: DHL,EMS,UPS or Fedex (fast and safer)

3)Located in manufacturing base of hebei shijiazhuang city,we also help customer design according to customers’ requirements and products’ application.

Application:Stairs, Furniture install etc.

Material:Carbon steel / cold rolled sheet /hot rolled sheet /spcc Stainless steel ( 201, 304, 316)Aluminium steel ( 5052 , 6061 , 7075 ) Brass / plactic / copper

Main Equipment

CNC Machining Center (cnc milling ,cnc truning ),CNC Lathe ,Etc.Laser cutting machines , Drilling machines ,Etc.

Bending machines , stamping machines ,punching machines ,welding machines ,Etc

Tube laser cutting machines ,Robert welder,Etc.

Finish:Hot dip galvanized , cold dip galvanized , zinc plating-coloring , powder coating ,Etc .Sandblasting, Anodizing Color, Blackenning, Polishing And Brushing,Etc.

Delivery time :3-7 days for sample.Mass production depends on the quantity

Drawing FomartStep,Stp,Gis,Cad,Pdf,Dwg,Dxf Etc Or Samples.

MOQ:100pcs

Quality Control:First inspection, patrol inspection, final inspection . 100% inspection .

Tolerance:Bending : 0 ~ +/-0.1mm;CNC machining :+/-0.02mm ~ +/-0.05mm;

Laser cutting :+/-0.05mm ~ +/-0.1mm

Material:Metal, Steel, stainless steel, aluminum, Iron, copper, brass etc.

Process:Stamping, laser cutting, CNC bending, CNC machining, milling, casting, forging, robot welding etc.

Surface Treatment:Zinc plated, Nickel plated, Chrome plated, Anodized, Electropolish, Brushed, powder coat, painting, electrophoresis, Shot blasted, phosphorylated,pickling etc.

OEM ServiceKindly send your drawings or original samples

Samples:Quick prototype, Free sample

Tolerance :+/-0.01mm to +/- 0.1mm

Payment Terms:T/T, L/C at sight, Western Union,

Product detail pictures:

Related Product Guide:

Normally customer-oriented, and it's our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for Factory source Laser Cutting Machine Components - Laser cutting (cutting,bending, welding) – Tuoou, The product will supply to all over the world, such as: kazan, Macedonia, Niger, We're your reliable partner in the international markets of our products and solutions. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade solutions in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We're willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.